|

Show Me Shortline offers a NEW 10ft bagger called the R1090. This machine provides grain compaction with no loss or damage to the grain. We have been selling baggers to all types of farmers, and any grain can be stored in grain bags including but not limited to soybeans, corn, wheat and rice. You can tag your bags if you have multiple types of grain and even detail what the moisture is, what field it was harvested from and the date of harvest right on the bag.

The R1090 is the most popular bagger for us. This 10ft bagger can bag about 39, 000 bushels an hour of grain. This bagger is the best for medium to large scale farming operations because with the longest bag we sell (a 10ft x 333ft long bag) you can store up to 16, 400 bushels in just one bag. But the possibilities of a grain bagger are endless, and are not limited to storing grain directly on your farm. With a grain bagger one could provide storage space for commercial grain silos, mills, ethanol plants or grain drying facilities just to name a few. The Richiger R1090 parts depo is conveniently located in the middle of the country, in Centralia, MO, and although few parts are needed because farmers have had little issues with the Richiger baggers, you can be assured we have the parts you might need. Some reasons that make the Richiger R1090 so popular is that it has been proven reliable, it is simple to operate and it has great compaction which eliminates grain loss. A Richiger R1090 can be run by one producer, eliminating the need for multiple staff on hand. |

The newest unloader for 9 or 10ft bags is the Richiger E6910.

In the early 2000’s, Richigers research and development resulted in the first ever automatic grain bag unloader. Even today, all bag unloaders on the market are designed after Richigers hydraulic roller principle that was conceived back then. An ongoing commitment to technical excellence ha snow produced the trim and distinctive E6910 model, the highest output machine to date, with no need for extra horsepower. This grain bag unloader will unload grain at the rate of 13,800 bushels per hour. That’s impressive! Some standard features include quick access hatch for drive chain lubrication and servicing, large capacity roller that can store up to 600ft of used plastic, a single auger extension that is easily removed to convert from 10’ to 9’ unloading capacity, a 15” discharge auger that will deliver that large 13,800 bushels per hour of unloaded grain and an all new mechanism that connects and disconnects the roll drive automatically which eliminates the difficulty of aligning and inserting lock pins manually. It is also very simple to move this bag unloader from transport to working position. The height regulation for transport and work is set hydraulically and cylinder clamps are used to ensure steadiness in operation. Other hydraulic functions include raising and lowering discharge auger, setting clearance to the ground, turning the roller, and regulating its speed. Customers who have experienced this grain unloader are often amazed at how efficiently and quickly the grain is unloaded, there are not multiple machines or labor needing in this process, the unloader works quickly to unload the grain and the bag is then slipped off the unloader for fast recycling or disposal. |

|

Show-Me Shortline offers a 9ft bagger called the R950. This machine provides grain compaction with no loss or damage to the grain. We have been selling baggers to all types of farmers, and any grain can be stored in grain bags including but not limited to soybeans, corn, wheat and rice. You can tag your bags if you have multiple types of grain and even detail what the moisture is, what field it was harvested from and the date of harvest right on the bag.

The R950 can bag 12,000 bushels an hour of grain. The horsepower needed to run this bagger is 45HP. The possibilities of a grain bagger are endless, and are not limited to storing grain directly on your farm. With a grain bagger one could provide storage space for commercial grain silos, mills, ethanol plants or grain drying facilities just to name a few. The R950 is great for the medium to small producer and handles 9ft in width bags. The Richiger R1050 parts depo is conveniently located in the middle of the country, in Centralia, MO, and although few parts are needed because farmers have had little issues with the Richiger baggers, you can be assured we have the parts you might need. The Richiger R950 has been proven reliable, it is simple to operate and it has great compaction which eliminates grain loss. A Richiger R950 can be run by one producer, eliminating the need for multiple staff on hand. |

This unloader will unload 9 or 10ft bags and can unload a bag in approximately 1,000 bushels in 5 minutes, 12,000 bushels in 1 hour.

We sell this unloader for a variety of reasons, but speed and easy operation are two of the main reasons. This grain bag unloader features a new chain and gear transmission that reduces needed hydraulic motor rpm. The automatic roller engages and disengages plastic so it can release plastic very quickly. There is a reception chamber that includes a new scooped pusher that creates unmatched delivery of grain to the discharge auger. There will be no grain flow turbulence because the Richiger EA910 grain bag unloader has an all new auger drive that is positioned away from the reception chamber. The grain can move fast through the auxiliary hopper because there is a sliding partition that seals the reception chamber and speeds up the passage of grain. You can easily connect and disconnect the sweeper augers with a simple pull type locking mechanism. It is also very simple to move this bag unloader from transport to working position. The height regulation for transport and work is set hydraulically and cylinder clamps are used to ensure steadiness in operation. Other hydraulic functions include raising and lowering discharge auger, setting clearance to the ground, turning the roller, and regulating its speed. Customers who have experienced this grain unloader are often amazed at how efficiently and quickly the grain is unloaded, there are not multiple machines or labor needing in this process, the unloader works quickly to unload the grain and the bag is then slipped off the unloader for fast recycling or disposal. R950MX Roller Mill Bagger.Richiger R950MX Roller Mill Bagger. Two Machines in One: increasing efficiency.

One of the unique machines we feature in the Richiger Flexi-Grain Storage Systems lineup is the Richiger R950MX Grain crimping roller mill bagger. This machine can output approximately 3,150 bushels per hour, making it the largest 9ft crimper-bagger in the business. The Richiger R950MX bagger saves time and money because once crimped and ensiled using the R950MX, the grain undergoes lactic fermentation because it has a lack of oxygen, so no further processing is required afterward. Therefore, you save on money and energy because your grain does not have to be dried. Crimped grain with this bagger is dust free, so it is healthier for you, your workers, and livestock. You can harvest an average of 3 weeks before conventional dates with a 950MX bagger, at the peak of nutritional value-and before most fungal diseases emerge. The grain that comes from being crimped, then bagged, is ideal for livestock from calves to sheep along with dairy and beef cattle because they digest it better due to its high concentrated nature. All grains that are harvested with a combine can be crimped with the Richiger R950MX bagger. In regards to moisture, Cereals are generally bagged at 30%-40% moisture, pulses at 30%-35%, and corn around 25%-33%. This is a unique machine because it is essentially two machines in one, streamlining the process of crimping and bagging grain. Other features of the Richiger R950MX include choice of roller grooves: you can choose between 4, 6, or 9 teeth per inch for different sizes of desired grain; large industrial type tires, command station to allow you to monitor brake pressure and make sure you are packing the bags well; and dividers in the hopper so both roller mills get equal amounts of grain. The Department of Animal Sciences from the University of Missouri, in reference to corn and milo harvested early for use as high grain feed for beef cattle, said this: “There may be as much as 10% improvement in the feed value of the grain for cattle.” “Field losses at harvest may be reduced by 5-10%. Losses average about 13% FOR 15% moisture grain vs. 2% for 26% moisture grain.” (In regards to field grain losses diminishing when combining ahead of time). |

CG300 Truck Unloader.

The Richiger RTU1250LP is a high performance truck unloading auger, and is an excellent match for our Richiger Grain Bagging System and can attached with any Richiger Grain Bagger. It features and optional assist mover with hopper and mechanical drive and has quick disconnect for grain bagger use only.

This easy to use unit transports as one unit, so the width of the bagger in transport mode is maintained. It is also quick and easy to set up operation of the RTU1250LP truck unloading auger. It has great truck to bag clearance and is hopper bottom or rear dump capable.

This easy to use unit transports as one unit, so the width of the bagger in transport mode is maintained. It is also quick and easy to set up operation of the RTU1250LP truck unloading auger. It has great truck to bag clearance and is hopper bottom or rear dump capable.

Check out our website exclusively dedicated to Grain Bagging!

Grain Bags.

|

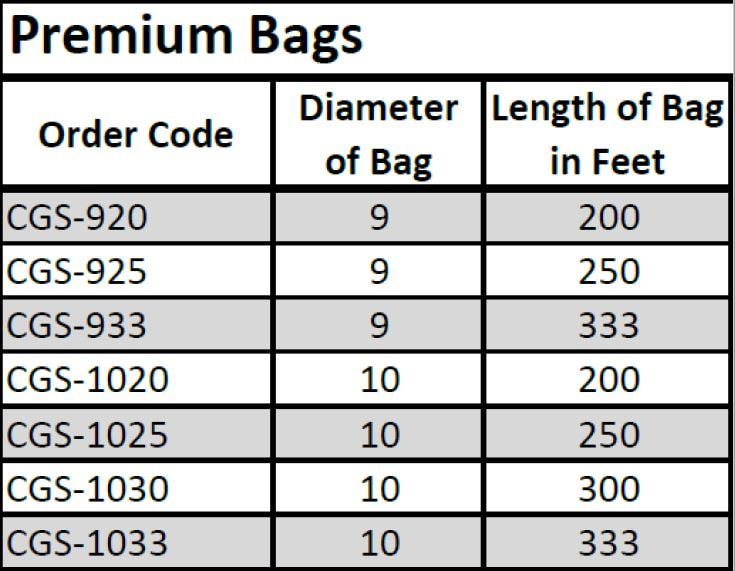

Plastar is the brand of grain bags that we sell to accompany our Richiger Grain Bagging Systems. Plastar bags are offered in 9 or 10 feet in width by up to 333 feet in length.

We offer Plastar Grain bags that are the thickest in the industry at 9.3 mil. Although others might claim that bags are thicker, our bags have been tested and are at the highest in the market. Our grain bags are reasonably priced and can save you time and money by bagging your grain in the field. |

Grain bag Frequently Asked Questions Answered! |